Shock Thermal Air Test Chamber:

The equipment is divided into three sections: the high temperature chamber, the low temperature chamber and the testing chamber.The TFT LCD touch panel controller was made in Japan, can display Chinese / English. Big size TFT LCD panels are also adopted.High formula memory capacity can be set to 120 patterns. The maximum cycle setting is 9999 times. The maximum setting of each section is 999 Hrs 59 Mins.Provide with RS-232C communication interface device, capable of controlling / editing/ recording in the linkage with the computer and two set dynamic connection point and convenient application.Both 2 zone and 3 zone shocks can be chosen.All equipments are fully automatic, and all process are precisely controlled with PLC.If any parts have errors, the machine will automatically shuts down and a warning light switches on.Machine can be shut down automatically in case of electrical power instabilities.

Main Features:

1. Large color LCD touch interactive microcomputer control system easy to understand running at a glance

2. Closed imported compressor + environmental refrigerant, cold plate heat exchanger and dual-type

ultra-low temperature refrigeration systems;

3. A LAN network communication interfaces to computer remote control, easy to use

4. Independently set the heat, cold and hot and cold conditions, the impact of three different function, the impact of the implementation of hot and cold conditions, with high and low temperature testing machine functions

5. Operation at boot time automatically make an appointment ahead of pre-cooling, preheating, standby

6. Defrost cycles can be set and the number of automatic (manual) defrost

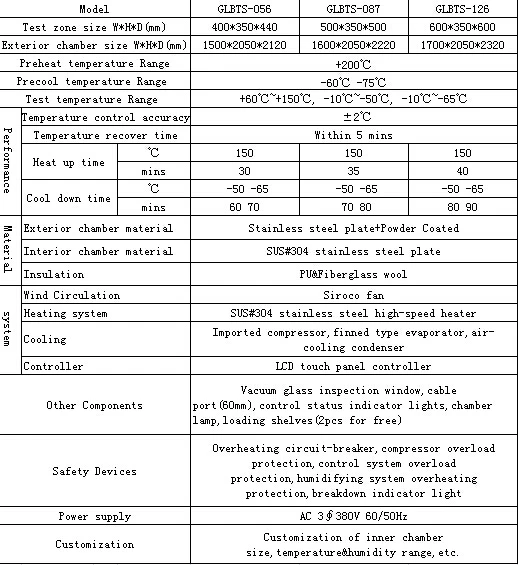

Specifications:

Two-layer Air Thermal Shock Test Chamber

1.Warranty for 1 years

2.hight,low and test area

3. Factory price